Anti Seize Compounds

TAS 6000 EP Anti Seize Bearing Grease

(650°F / 343°C)

TAS 6000EP was developed specifically for slow to medium speed, plain and anti-friction bearings. The low volatility and non-carbonizing, smokeless properties of this grease make it desirable for “hard-to-get-to” bearings needing extended lube cycles.

- Water and chemical resistant

- Non-melting

- Extends lube cycles

- Slow to Medium Speeds

- PTFE Fortified

- Sealant Lubricant

- O-Ring assembly compatibility

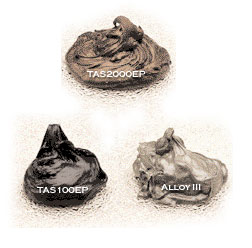

TAS 100 EP Solid Film Lubrication

(750°F / 400°C)

TAS 100EP is a special anti seize compound that lubricates as a grease, and provides solid film lubrication in extreme temperatures. Non-melting with a heavy concentration of Moly- MoS2 for maximum protection.

- Slow speeds in anti-friction, plain or sleeve bearings

- Excellent for stainless steel applications

- Exceptional plating properties

- Protects Against Galling And Seizing

ALLOY 111 Anti Seize Compound

ALLOY 111 is a combination of metallic solids and special additives for maximum metal protection. ALLOY III paste creates a long lasting lubricating seal between mated metal surfaces. This nickelcolored compound has a smooth texture that makes it desirable for press fit, sleeve and threaded applications of all types.

- Easy Spreadability

- Mining Applications—Revolving Bit Lube

- Superior Metal plating eliminates fretting and galvanic action.

TAS 2000 EP Copper Anti Seize

(1800°F / 980°C)

Copper anti seize compound offers extraordinary plating properties to eliminate welding and seizure of metal surfaces when exposed to extreme pressure and high temperature.

- Brake Parts

- Spark Plugs

- Boiler Assemblies and Coke Ovens

- Threaded Connections

- Flange Bolts

- Oven Accessories

Typical Applications

- Threaded Connections such as Nuts, Bolts, Screws, Pipes & Studs

- Bushings, Cams, Ways, Rails, Slides

- Pump Connections, Well Pumps

- High Temperature Oven Accessories

- Engine Cylinder Head Studs

- Exhaust Manifolds

- Wheel Studs

- Cover Plate Studs

- Flange Bolts

- Assembly Paste

Typical Properties

| Product | Tas 100 Ep | tas 2000 ep | Tas 6000 ep | Alloy 111 |

|---|---|---|---|---|

| NLGI | 3 | 1 | 1.5 | 2 |

| Worked Penetration | ||||

| @ 770F / 250C | 225-245 | 295/310 | 295-310 | 270-280 |

| Base oil Viscosity | ||||

| SUS @ 100 0F | 2110 | 2225 | 1050 | 2940 |

| cSt @ 40 0C | 456 | 480 | 226 | 634 |

| Color | Gray | Metalic Copper | White | Metalic Gray |

| Solids | >65% | >58% | >45% | >40% |

| Water Resistance | Good | Excellent | Excellent | Very Good |

| Chemical Resistance | Good | Excellent | Excellent | Very Good |

| Operating Range | ||||

| 0F | -0/750 | -40/1800 | -35/650 | -5/575 |

| 0C | -18/399 | -40/980 | -37/343 | -20/302 |