Tribology Tech-Lube’s High-Performance Food Grade Grease: Engineered for Efficiency

Tribology Tech-Lube’s High-Performance Food Grade Grease:

Engineered for Efficiency

In industries that include bakeries, dairies, and beverage production, keeping a clean and safe environment is necessary. Equipment in these facilities must not only meet food safety standards but also perform reliably under demanding conditions. Tribology Tech-Lube’s high-performance food-grade greases are designed to meet these needs, offering superior lubrication that improves equipment performance while complying with food safety regulations.

Meeting the Needs of Food Production

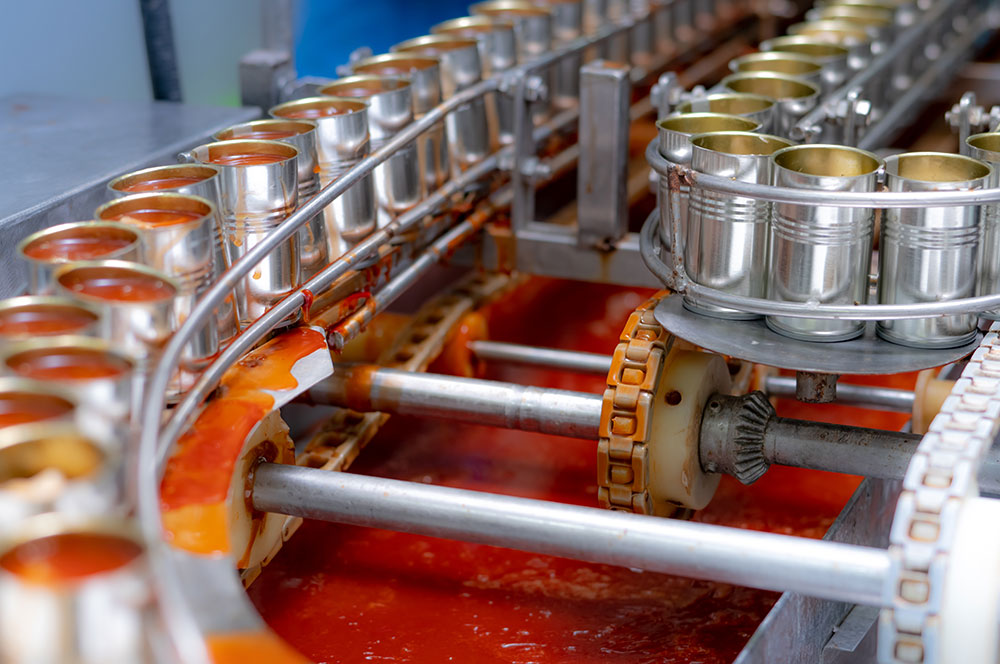

Food processing environments present lubrication challenges. Equipment like mixers, conveyors, filling machines, and packaging lines are usually exposed to moisture, heat, and washdowns. These conditions can cause standard greases to break down, causing increased friction, wear, and contamination risks. Tribology Tech-Lube’s food-grade grease can withstand these challenges and offer lubrication that keeps equipment running at its smoothest.

Our NSF H1-registered food-grade grease is safe for incidental contact with food, ensuring compliance with industry regulations. It is designed to resist water washout, making it ideal for environments where equipment is regularly cleaned. Additionally, it offers excellent adhesion, staying in place even under high-speed operations, which is particularly important in industries like beverage bottling and dairy processing.

Improving Efficiency in Key Industries

Bakeries

Equipment in bakeries, like conveyors, dough mixers, and ovens, are almost always under stress. The high temperatures and common cleaning cycles can make standard greases degrade and this can increase maintenance and downtime. Tribology Tech-Lube’s food-grade grease provides consistent performance, reducing friction and wear on moving parts. This helps bakeries maintain smooth operations, minimize equipment failures, extend the life of their machinery, and reduce downtime.

Dairies

Dairy processing involves equipment like pasteurizers, homogenizers, and filling machines that are exposed to moisture and repeated washdowns. Our food-grade greases are resistant to water washout and provides rust and corrosion protection. This ensures that dairy equipment operates reliably, even in wet conditions, reducing the risk of unplanned downtime and costly repairs.

Beverage Production

Beverage production lines, including bottling and canning operations, require lubrication that can perform well at extreme high speeds and constant use. Tribology Tech-Lube’s food-grade grease can handle these demands by providing load-carrying capacity and wear protection. This helps beverage producers maintain production rates and reduce maintenance frequency.

Why Choose Tribology Tech-Lube?

Tribology Tech-Lube delivers quality products with quick turnaround times. We can ship our food-grade grease within 1-2 weeks to make sure that our customers receive the lubrication solutions they need without delay. Our ISO certification reflects our dedication to quality and consistency, giving customers confidence in the products they use.

What sets us apart is our focus on building strong relationships with our clients. We understand that every facility has its own needs, and we work with our customers to provide solutions that meet their requirements. Our food-grade greases are not a commodity product—they are specialized solutions that deliver real results.

The Impact of Quality Lubrication

Using a lubricant like Tribology Tech-Lube’s food-grade grease can make a big difference in food production facilities. It reduces wear and tear on machinery, lowering maintenance costs and extending the lifespan of equipment. By decreasing friction and heat generation, it also improves energy efficiency, contributing to operational savings.

Experience the Difference

If you’re looking for a lubrication solution that combines food safety compliance with exceptional performance, Tribology Tech-Lube’s high-performance food-grade greases are the answer. Contact us today to learn more about how our products can help your bakery, dairy, or beverage facility operate more efficiently.